My questions are: is there a way to remove the double outline? Is there something else I should do? Is there another program that would be better for me to use?Īny help at all would be greatly appreciated. Part of this I can fix by eliminating arc in/arc out, part of it I can not. I kept adding additional layers and it would only allow me to do a small piece of each segment at a time, but, again, identical elements in another part of the cut would work fine. Part of the time I get errors telling me that I can't cut this small, but it does that even when I blow it up very large (I tried to cut a keychain holder earlier tonight at 30"x14" and it still did the same thing). I have spent countless hours trying to figure this out and trying all sorts of different settings both in Corel and in Sheetcam. The weird thing, is that I can have two identical items (like two R's and one will work and the other won't. If there are several sections to the cut, I can't possibly get all of it to work, ever. The problem is that when I try to set the paths in Sheetcam using the C tool, I have to do little bitty segments of the path at a time and some paths, even though they look good, I can't choose at all and some of them that do work only allow me to choose both paths at the same time.

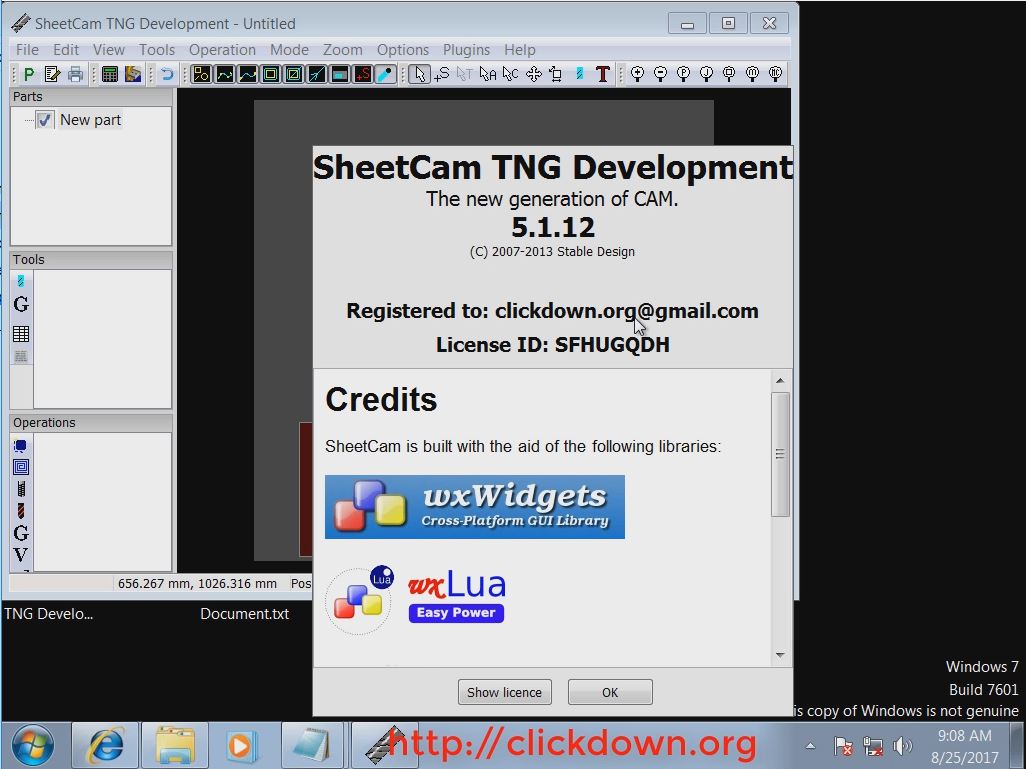

I still have two outlines of everything in Sheetcam. Part of the time, it creates a bunch of random junk and gets rid of most of the picture. Some of the times it seems to help, sometimes it doesn't. I read that I could use ARRANGE-WELD in Corel to fix this, so I tried this. When I then open in Sheetcam, I get two outlines. I do this and then I save the file as a dxf and then I use the DXFTOOL (because it seems that if I haven't already saved the file as a DXF, DXFTOOL will create an empty file). If I import an image into Corel, the only way I can get it to allow me to export using dxftool is by doing an outline trace.

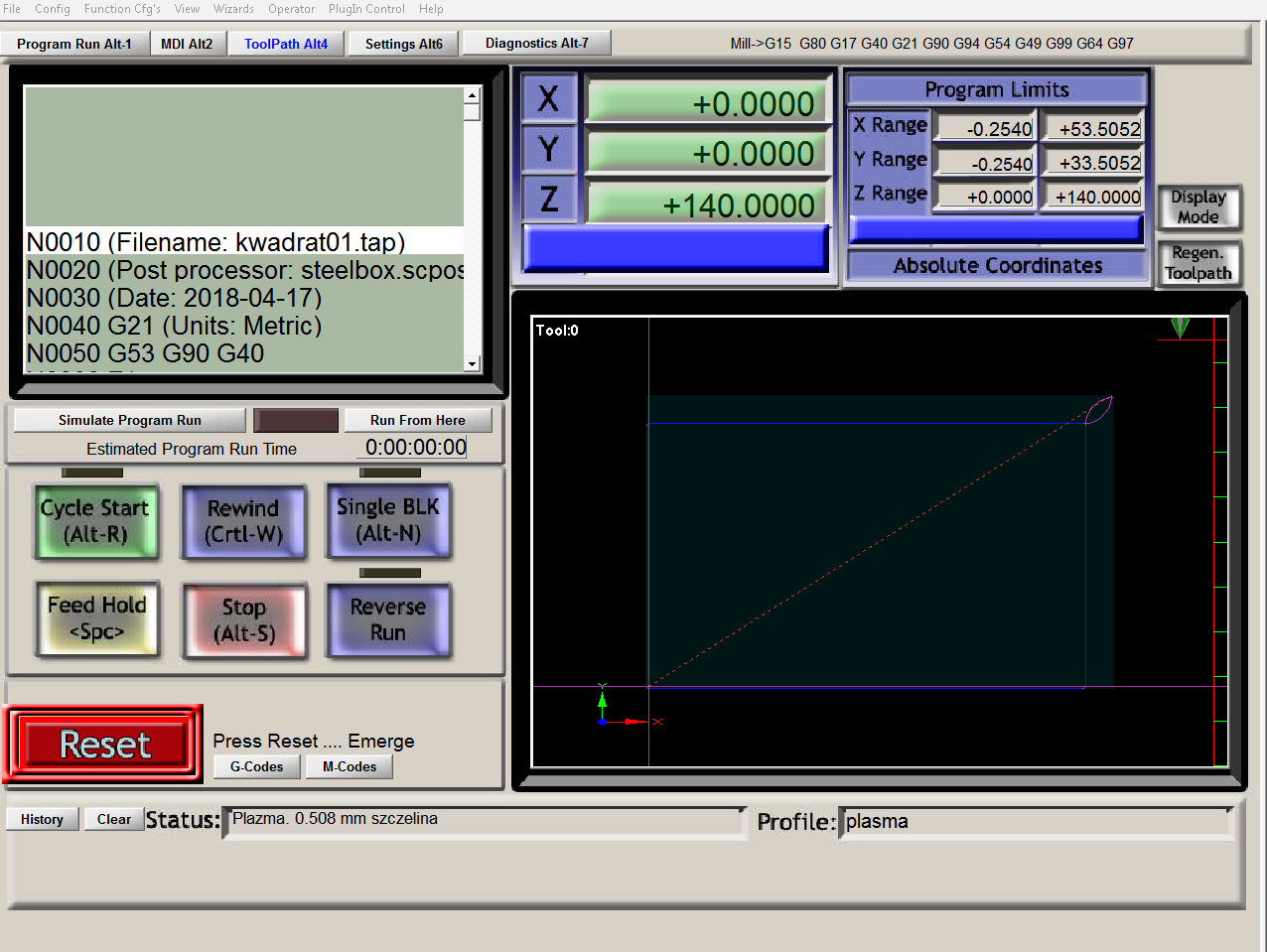

Here is where my problem comes into play. I bought the licenses for both after purchasing the table and installed these. and 40's drilled out the size of 60's work well too.). (I also can't get 40amp tips to work, they burn up very quickly, but 60's work very well even at lower amperage settings. (I am also trying to find additional "tools" and tool settings for this setup (I have plasma_short, medium and long) and the correct settings for different guages of sheet. I'm running Mach3 and using Sheetcam to create the GCODE. Anyway, I do have the system working overall pretty well. I would like to find a spot that has good tool settings for my setup though. I do have a recurring problem of the torch occassionally staying too high above the cut and not piercing until I stick a piece of metal in the arc, but most of my settings seem to be working pretty well. I have it down now to the point that I can cut anything that I create in Corel myself and dxfs that I get from some locations. I've run through a ton of problems over the last several months (mostly because I didn't understand what was going on, lol). I have a Plasmaroute 4x8 blaze table with a Thermal Dynamics A60 Cutmaster plasma torch. Hello, first of all, thank you in advance for your help (and for understanding that I'm a newbie who has spent a ton of hours trying to research this and figure it out before asking here).

0 kommentar(er)

0 kommentar(er)